The Company’s product range was expanded now boasts 15 new products, with five more grades under development. In particular, sales of seven new NPK grades started for high-margin crops in Latin America. Also expanded was the Company’s range of liquid products to complement the NPK Solar fertiliser line.

Uralchem was the first company in Russia to introduce MultiStart, a line of biomodified fertilisers, which was improved to suit a wider range of crops.

Uralchem also ran a series of field tests to use aerial drones for fertilisation, the first among other fertiliser producers. With this technique, fertiliser can be applied remotely in almost any conditions.

On 1 March 2023, Voskresensk Mineral Fertilisers JSC completed a reorganisation process and was merged with Uralchem as its branch. The reorganisation aims to increase Uralchem Group’s operating efficiency by reducing the number of intragroup transactions, considerably cut administrative and management expenses, and improve financial flow management.

In 2023, Uralchem Group’s humanitarian assistance included the supply of 20,000 tonnes of complex fertilisers to Malawi, 34,000 tonnes of fertilisers to Kenya, 23,000 tonnes of fertilisers to Zimbabwe, and 34,000 tonnes of fertilisers to Nigeria.

Uralchem Group is committed to donating approximately 300,000 tonnes of mineral fertilisers to developing nations to alleviate the unprecedented global food crisis and prevent crop losses in countries that face the risk of famine. The charity shipments to Africa are facilitated by the United Nations World Food Programme.

For the first time in its history, Uralchem appeared on the list of Russian leaders of sustainable development, corporate responsibility and reporting issued by the Russian Union of Industrialists and Entrepreneurs (RSPP). For its performance in 2023, Uralchem achieved a Group A (which is the highest group) ranking in the Sustainable Development Vector index and a Group B+ ranking in the Responsibility and Transparency index.

The Responsibility and Transparency index analyses the quality of corporate social responsibility disclosures and identifies priority directions for further development of sustainability practices, while the Sustainable Development Vector index assesses the environmental and social performance history of the participating organisations.

Uralchem shipped over 23,000 tonnes of the NPK fertilisers to Lomé, the capital of the Togolese Republic, from where the fertilisers were transported to Burkina Faso. The shipment was made completely free of charge and is part of Uralchem’s humanitarian project to supply fertilisers to African countries. In addition, Uralchem and Uralkali jointly delivered a 20,000 tonne batch of NPK fertilisers to Malawi via Mozambique.

The humanitarian project is part of Uralchem’s efforts to address the global food crisis and responds to UN Sustainable Development Goal No 2 — “End hunger, achieve food security and improved nutrition and promote sustainable agriculture”.

The publication of its first ESG report marked another step in Uralchem’s sustainability transformation journey and supported the implementation of the Company’s ESG Strategy adopted in 2021. Uralchem confirms its commitment to follow principles of sustainable development, support employee and community well-being, and contribute to food security.

The ESG Report was prepared in line with reporting standards of the Global Reporting Initiative (GRI) and Sustainability Accounting Standards Board (SASB).

Uralchem Innovations launched a pilot plant making pea isolate – a high-purity natural vegetable protection produced from yellow peas. The isolate can be used in meat and milk alternatives, sport and dietetic nutrition, gluten-free and protein-rich breads, groceries and pastries.

Located at the Skolkovo Centre of Innovations, the pilot plant also includes an agricultural and a chemical laboratory.

Uralchem launched production of complex mineral fertilisers at GEO NPK LLC in Chernyakhovsk (Kaliningrad Region, Russia). GEO NPK will be making products containing nitrogen, phosphorus, potassium, and other mesoelements and microelements in one granule. With this new operation, Uralchem’s product portfolio will be expanded by more than 100 fertiliser brands.

In addition, production of AdBlue was started in Yartsevo, Smolensk Region. AdBlue is a liquid chemical, which is used to treat diesel engine exhaust gases and which reduces the content of nitrogen oxides in exhaust gases by 90%. The monthly capacity of the new plant is about 1,250 tonnes with a possible expansion to 2,500 tonnes.

Uralchem’s Board of Directors approved the Company’s ESG Strategy until 2025. The document ensures a systemic approach to the development of sustainability practices and lays the foundation for a further ESG transformation of the business. Uralchem views the ESG Strategy as an integral part of its overall corporate strategy and plans to integrate the principles of sustainable development into all main business processes. The Company’s key priorities cover global issues, sustainable production, product quality and safety, environmental performance within areas of its operations, and well-being of employees.

At the request of Uralchem, Togliattiazot (ToAZ) held an extraordinary general shareholders’ meeting (EGM) on 27 November 2021. At the EGM, ToAZ shareholders resolved to terminate prematurely powers of the management company (Togliattiazot Corporation JSC) and members of the board of directors, followed by an election of a new board of directors. The resolutions of the EGM were aimed at improving the financial and economic efficiency of ToAZ, and restoring law and order at the enterprise. Uralchem conducted the EGM strictly in accordance with the applicable legislation and the final judgement of the Arbitrazh Court of the Samara Region dated 22 November 202.

The Group's holding companies, Uralchem Holding PLC and CI-Chemical Invest Limited, re-domiciled from Cyprus to Russia. Thus, the entire asset management chain of Uralchem Group is now located within the Russian Federation. Tax contributions from the previously foreign assets of the Group will now be flowing to the Russian budget.

New product of the Azot Branch – feed salt – conquers the market

New product of the Azot Branch – feed salt – conquers the market

Sodium chloride technical grade (feed salt) has become an important product in the company's line of feed additives. The entire volume of feed salt is sold in the domestic market. It is in demand by livestock breeders. The product is a mineral additive and is used to enrich the ration of cattle, poultry, and other domestic animals with sodium and chlorine. The production of feed salt became possible through the implementation of an investment project. Within the framework of the project, a new nitrite and nitrate facility was built, where sodium chloride crystals are converted into sodium chloride technical grade — feed salt.

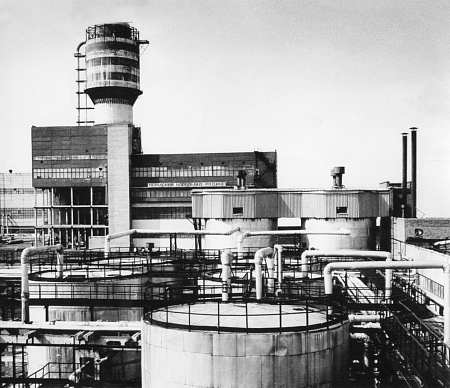

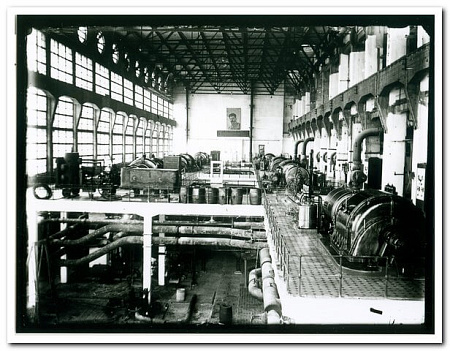

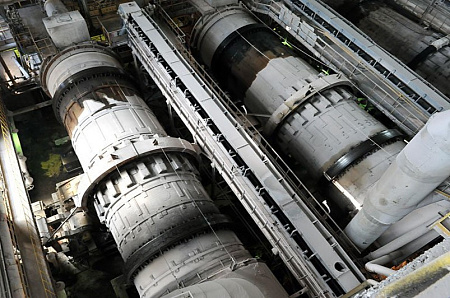

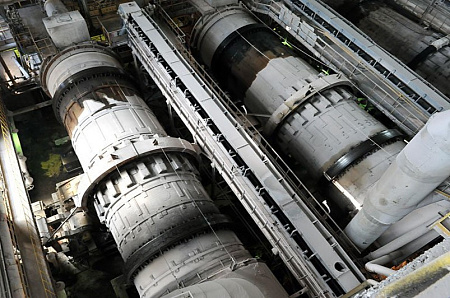

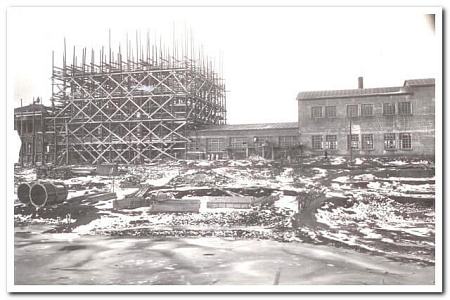

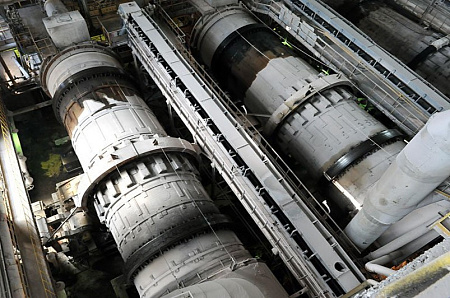

AM-76 ammonia unit at the KCKK Branch has been upgraded

AM-76 ammonia unit at the KCKK Branch has been upgraded

The URALCHEM Group allocated about 2 billion rubles for the repair and upgrade of the AM-76 ammonia unit. Such major works are carried out every twenty years. The reforming furnace pipes and lining were replaced. At the same time, an investment project was implemented to increase the unit's productivity; a syngas compressor was upgraded, which at that time was the bottleneck in the process chain. Almost all the plant's services and contractors took part in the work. As a result, the Company's specialists ensured reliable operation of the equipment and increased the capacity of the ammonia unit by 85 tons per day in winter.

URALCHEM was awarded the IFA gold medal

URALCHEM was awarded the IFA gold medal

The International Fertilizer Association (IFA) has awarded the PMU Branch of URALCHEM USC with the "Best in the Industry" gold medal for responsible production management. The PMU Branch was the first fertilizer producer in Russia to receive IFA certification under the Protect & Sustain program in August 2017. In February 2019, the plant successfully passed an intermediate check and confirmed the validity of this certificate.

A facility for urea packing in big bags was built at PMU

A facility for urea packing in big bags was built at PMU

The PMU Branch of URALCHEM USC received permission to put into operation a new facility for urea packing in soft containers (big bags). The corresponding certificate was signed by specialists of the Department of Urban Planning and Architecture of Perm on December 27, 2019.

The facility contains two high-speed filling machines and a transfer unit. The produced urea goes to the newly constructed building. In the packaging facility, the product is accumulated in bunkers, and then, using filling machines, is distributed into 800 kg big bags. A loading area with an overhead crane on stationary supports is equipped next to the packing facility. Here, urea bags are loaded into gondola cars. Also within the scope of the project, the construction of a gondola car preparation area continues. The total investment amounts to 530 million rubles. The result of the project implementation will be the opportunity, if necessary, to pack the entire volume of urea produced in the PMU Branch in big bags.

The investment project "Technical re-equipment of UKL-7 units and production of magnesium nitrate solution" of shop No. 5 was implemented. The project value is 254 million rubles.

After the upgrade, the capacity of the units has increased by more than 50 tons per day. Due to the elimination of an explosive substance – natural gas – operational safety has increased. The work carried out made it possible to increase the productivity of the units by at least 1 ton per hour, as well as to improve the environmental characteristics of production and improve the working conditions of employees.

During the upgrade of No. 5A department of the non-concentrated nitric acid production, work was also carried out to change the supply of circulating water to these units. The implemented actions resulted in the connection of additional circulating water facilities, which make it possible to increase the cooling efficiency of heat-exchange process equipment and to increase the reliability of circulating water supply due to the possibility of switching between water circulation cycles when eliminating defects and carrying out shutdown repairs in other workshops of the branch.

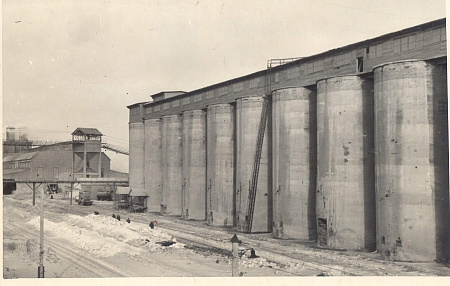

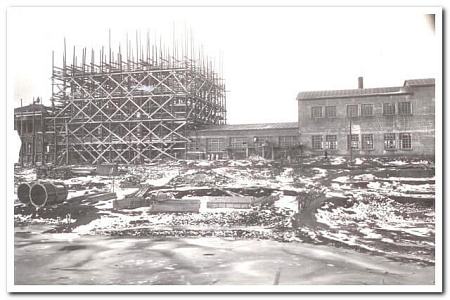

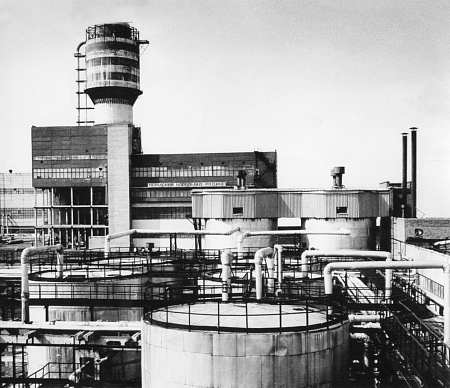

VMF has completed the second stage of a massive investment project for upgrade of sulfuric acid production

VMF has completed the second stage of a massive investment project for upgrade of sulfuric acid production

As part of the project, the A2 final absorption tower was replaced. During the shutdown period, the tower, which ensures the capture of pollutants before they are released into the atmosphere, was replaced. The cost of the second stage of the project amounted to 232 million rubles. In 2019, its successful completion allowed the enterprise to enter stable production of sulfuric acid at design loads. The implementation of the largest investment project in recent decades has been underway since 2017. It involves the phased replacement of three absorption towers. One of the world leaders in the production of sulfuric acid equipment, the Canadian company CHEMETICS, was chosen as the project designer and equipment supplier. The total value of the contract exceeds USD 10 million. The first tower was replaced in 2017.

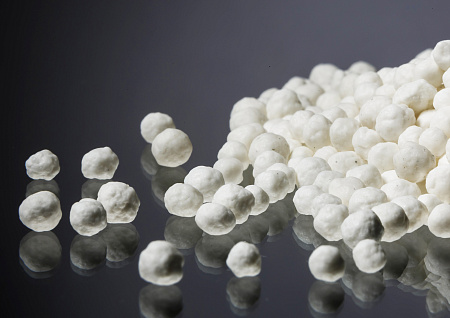

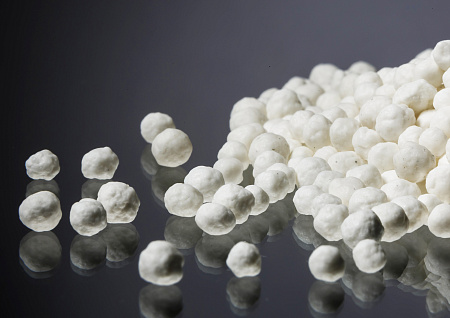

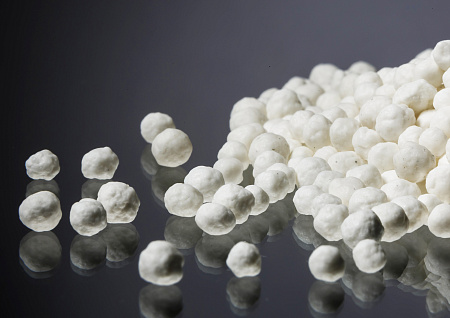

PMU Branch launched the production of micro-prilled urea

PMU Branch launched the production of micro-prilled urea

PMU Branch launched the production of micro-prilled urea with a grain size of 0.3-1.0 mm. For packaging this product a new building has been constructed on the Perm production site for the first time in decades. Project investment totalled 72 million roubles (VAT included). Samples of micro-prilled urea were sent to consumers and enjoyed very good feedback. As a result the company began export shipments of the new product. The maximum production and sales volume of micro-prilled urea at PMU Branch is estimated at 20 thousand tonnes a year. This is approximately 20% of the global consumption.

VMF improves the quality and increases the output of clarified phosphoric acid

VMF improves the quality and increases the output of clarified phosphoric acid

VMF Branch introduced a line of new filter presses designed to improve the quality and increase the output of clarified phosphoric acid. This technical solution was dictated by the company’s needs for a high-quality pure product, since it directly affects the quality of water-soluble fertilisers, for which the clarified acid is the main semi-finished product. Today, the output of 100% clarified P2O5 is 50 thousand tonnes per year. The inclusion of new plants created additional opportunities for the sale of this commercial product. The demand for P2O5 in the chemicals market has been steadily growing.

KCCW Branch started the ‘Online Advisor for DGD’ project

KCCW Branch started the ‘Online Advisor for DGD’ project

At the end of 2018, as part of the digitalisation programme called ‘Artificial Intelligence and Machine Learning’, KCCW Branch started the implementation of an online advisor for a pilot drum type granulator-dryer (DGD). At the initial phase of the project, SAP in partnership with BDO developed a digital model of the drying and granulation process and trained a dedicated advisor. Historical data tests proved the sufficient accuracy of the digital model. A joint team of the customer and the contractor confirmed the potential efficiency of the project.

The online advisor implementation is a pilot project related to efficiency improvement of URALCHEM’s production processes.

On 1 August 2017, URALCHEM, JSC completed the reorganisation process in the form of merging Mineral Fertilizers, JSC (Perm) with URALCHEM, JSC as PMF Branch, with the termination of the activities of Mineral Fertilizers, JSC as an independent legal entity. The purpose of the reorganisation was to improve the efficiency of the companies comprising URALCHEM Group.

Voskresensk Mineral Fertilizers, JSC (VMF) has produced the first batch of a new range of water-soluble compound fertilisers for the open ground, under the Aqua Drop brand. They include six grades of compound nitrogen-potash (NK) and nitrogen-phosphate-potash (NPK) fertilisers. Their composition is different in a few ways from Solar fertilisers; for their production, other raw materials are used, which have been proven to be effective in the open ground. The company can now manufacture a highly effective and affordable type of agrochemical.

In addition, VMF has started the production of water-soluble Solar MAP and Solar NPK fertilisers sold at retail under the URALCHEM trademark and packaged in sealed bags of 1 kg, in addition to the production of granulated potassium chloride and NPK fertilisers of various grades. The use of small bags is because of the high demand for fertilisers from gardeners and small farmers.

Agreements on incorporation of URALCHEM’s own dealerships in the Russian regions are signed with governments of various areas of the Central, Southern, Volga, Far East, and Siberian Federal Districts. As of the year end, seven points of the holding products sales were opened in the Russian regions.

VMF has switched to commercial production of water-soluble fertilizers. Implementation of the major investment project began in 2011. It resulted in development of the state-of-the-art process of water-soluble MAP production from wet-process phosphoric acid, a process with no global peers. MAP is both a fertilizer as it is, and a feedstock for production of complex water-soluble fertilizers.

Within the scope of the national program of import phase-out, Azot Branch commenced production of granulated amine. The project, valued in excess of 110 million rubles, has been implemented jointly with Uralkali specialists. This product can be widely used in the mining, pharmaceutical, chemical, and other industries. It fully corresponds to its foreign analogues, but it is cheaper and logistically more convenient.

USC was created in early 2013 to unify and optimize URALCHEM divisions' accounting processes in a single multifunctional center. In particular, to process financial information and prepare financial reports by Russian and international standards, manage tax records and treasury operations as well as establish and maintain unified information and telephone systems of the Company.

The Company’s product range was expanded now boasts 15 new products, with five more grades under development. In particular, sales of seven new NPK grades started for high-margin crops in Latin America. Also expanded was the Company’s range of liquid products to complement the NPK Solar fertiliser line.

Uralchem was the first company in Russia to introduce MultiStart, a line of biomodified fertilisers, which was improved to suit a wider range of crops.

Uralchem also ran a series of field tests to use aerial drones for fertilisation, the first among other fertiliser producers. With this technique, fertiliser can be applied remotely in almost any conditions.

On 1 March 2023, Voskresensk Mineral Fertilisers JSC completed a reorganisation process and was merged with Uralchem as its branch. The reorganisation aims to increase Uralchem Group’s operating efficiency by reducing the number of intragroup transactions, considerably cut administrative and management expenses, and improve financial flow management.

In 2023, Uralchem Group’s humanitarian assistance included the supply of 20,000 tonnes of complex fertilisers to Malawi, 34,000 tonnes of fertilisers to Kenya, 23,000 tonnes of fertilisers to Zimbabwe, and 34,000 tonnes of fertilisers to Nigeria.

Uralchem Group is committed to donating approximately 300,000 tonnes of mineral fertilisers to developing nations to alleviate the unprecedented global food crisis and prevent crop losses in countries that face the risk of famine. The charity shipments to Africa are facilitated by the United Nations World Food Programme.

For the first time in its history, Uralchem appeared on the list of Russian leaders of sustainable development, corporate responsibility and reporting issued by the Russian Union of Industrialists and Entrepreneurs (RSPP). For its performance in 2023, Uralchem achieved a Group A (which is the highest group) ranking in the Sustainable Development Vector index and a Group B+ ranking in the Responsibility and Transparency index.

The Responsibility and Transparency index analyses the quality of corporate social responsibility disclosures and identifies priority directions for further development of sustainability practices, while the Sustainable Development Vector index assesses the environmental and social performance history of the participating organisations.

Uralchem shipped over 23,000 tonnes of the NPK fertilisers to Lomé, the capital of the Togolese Republic, from where the fertilisers were transported to Burkina Faso. The shipment was made completely free of charge and is part of Uralchem’s humanitarian project to supply fertilisers to African countries. In addition, Uralchem and Uralkali jointly delivered a 20,000 tonne batch of NPK fertilisers to Malawi via Mozambique.

The humanitarian project is part of Uralchem’s efforts to address the global food crisis and responds to UN Sustainable Development Goal No 2 — “End hunger, achieve food security and improved nutrition and promote sustainable agriculture”.

The publication of its first ESG report marked another step in Uralchem’s sustainability transformation journey and supported the implementation of the Company’s ESG Strategy adopted in 2021. Uralchem confirms its commitment to follow principles of sustainable development, support employee and community well-being, and contribute to food security.

The ESG Report was prepared in line with reporting standards of the Global Reporting Initiative (GRI) and Sustainability Accounting Standards Board (SASB).

Uralchem Innovations launched a pilot plant making pea isolate – a high-purity natural vegetable protection produced from yellow peas. The isolate can be used in meat and milk alternatives, sport and dietetic nutrition, gluten-free and protein-rich breads, groceries and pastries.

Located at the Skolkovo Centre of Innovations, the pilot plant also includes an agricultural and a chemical laboratory.

Uralchem launched production of complex mineral fertilisers at GEO NPK LLC in Chernyakhovsk (Kaliningrad Region, Russia). GEO NPK will be making products containing nitrogen, phosphorus, potassium, and other mesoelements and microelements in one granule. With this new operation, Uralchem’s product portfolio will be expanded by more than 100 fertiliser brands.

In addition, production of AdBlue was started in Yartsevo, Smolensk Region. AdBlue is a liquid chemical, which is used to treat diesel engine exhaust gases and which reduces the content of nitrogen oxides in exhaust gases by 90%. The monthly capacity of the new plant is about 1,250 tonnes with a possible expansion to 2,500 tonnes.

Uralchem’s Board of Directors approved the Company’s ESG Strategy until 2025. The document ensures a systemic approach to the development of sustainability practices and lays the foundation for a further ESG transformation of the business. Uralchem views the ESG Strategy as an integral part of its overall corporate strategy and plans to integrate the principles of sustainable development into all main business processes. The Company’s key priorities cover global issues, sustainable production, product quality and safety, environmental performance within areas of its operations, and well-being of employees.

At the request of Uralchem, Togliattiazot (ToAZ) held an extraordinary general shareholders’ meeting (EGM) on 27 November 2021. At the EGM, ToAZ shareholders resolved to terminate prematurely powers of the management company (Togliattiazot Corporation JSC) and members of the board of directors, followed by an election of a new board of directors. The resolutions of the EGM were aimed at improving the financial and economic efficiency of ToAZ, and restoring law and order at the enterprise. Uralchem conducted the EGM strictly in accordance with the applicable legislation and the final judgement of the Arbitrazh Court of the Samara Region dated 22 November 202.

The Group's holding companies, Uralchem Holding PLC and CI-Chemical Invest Limited, re-domiciled from Cyprus to Russia. Thus, the entire asset management chain of Uralchem Group is now located within the Russian Federation. Tax contributions from the previously foreign assets of the Group will now be flowing to the Russian budget.

New product of the Azot Branch – feed salt – conquers the market

New product of the Azot Branch – feed salt – conquers the market

Sodium chloride technical grade (feed salt) has become an important product in the company's line of feed additives. The entire volume of feed salt is sold in the domestic market. It is in demand by livestock breeders. The product is a mineral additive and is used to enrich the ration of cattle, poultry, and other domestic animals with sodium and chlorine. The production of feed salt became possible through the implementation of an investment project. Within the framework of the project, a new nitrite and nitrate facility was built, where sodium chloride crystals are converted into sodium chloride technical grade — feed salt.

AM-76 ammonia unit at the KCKK Branch has been upgraded

AM-76 ammonia unit at the KCKK Branch has been upgraded

The URALCHEM Group allocated about 2 billion rubles for the repair and upgrade of the AM-76 ammonia unit. Such major works are carried out every twenty years. The reforming furnace pipes and lining were replaced. At the same time, an investment project was implemented to increase the unit's productivity; a syngas compressor was upgraded, which at that time was the bottleneck in the process chain. Almost all the plant's services and contractors took part in the work. As a result, the Company's specialists ensured reliable operation of the equipment and increased the capacity of the ammonia unit by 85 tons per day in winter.

URALCHEM was awarded the IFA gold medal

URALCHEM was awarded the IFA gold medal

The International Fertilizer Association (IFA) has awarded the PMU Branch of URALCHEM USC with the "Best in the Industry" gold medal for responsible production management. The PMU Branch was the first fertilizer producer in Russia to receive IFA certification under the Protect & Sustain program in August 2017. In February 2019, the plant successfully passed an intermediate check and confirmed the validity of this certificate.

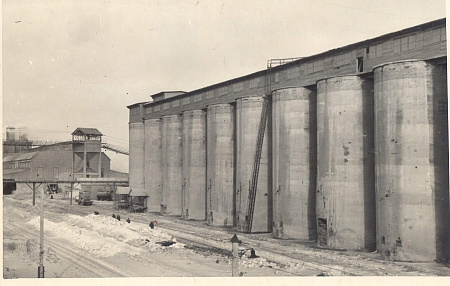

A facility for urea packing in big bags was built at PMU

A facility for urea packing in big bags was built at PMU

The PMU Branch of URALCHEM USC received permission to put into operation a new facility for urea packing in soft containers (big bags). The corresponding certificate was signed by specialists of the Department of Urban Planning and Architecture of Perm on December 27, 2019.

The facility contains two high-speed filling machines and a transfer unit. The produced urea goes to the newly constructed building. In the packaging facility, the product is accumulated in bunkers, and then, using filling machines, is distributed into 800 kg big bags. A loading area with an overhead crane on stationary supports is equipped next to the packing facility. Here, urea bags are loaded into gondola cars. Also within the scope of the project, the construction of a gondola car preparation area continues. The total investment amounts to 530 million rubles. The result of the project implementation will be the opportunity, if necessary, to pack the entire volume of urea produced in the PMU Branch in big bags.

The investment project "Technical re-equipment of UKL-7 units and production of magnesium nitrate solution" of shop No. 5 was implemented. The project value is 254 million rubles.

After the upgrade, the capacity of the units has increased by more than 50 tons per day. Due to the elimination of an explosive substance – natural gas – operational safety has increased. The work carried out made it possible to increase the productivity of the units by at least 1 ton per hour, as well as to improve the environmental characteristics of production and improve the working conditions of employees.

During the upgrade of No. 5A department of the non-concentrated nitric acid production, work was also carried out to change the supply of circulating water to these units. The implemented actions resulted in the connection of additional circulating water facilities, which make it possible to increase the cooling efficiency of heat-exchange process equipment and to increase the reliability of circulating water supply due to the possibility of switching between water circulation cycles when eliminating defects and carrying out shutdown repairs in other workshops of the branch.

VMF has completed the second stage of a massive investment project for upgrade of sulfuric acid production

VMF has completed the second stage of a massive investment project for upgrade of sulfuric acid production

As part of the project, the A2 final absorption tower was replaced. During the shutdown period, the tower, which ensures the capture of pollutants before they are released into the atmosphere, was replaced. The cost of the second stage of the project amounted to 232 million rubles. In 2019, its successful completion allowed the enterprise to enter stable production of sulfuric acid at design loads. The implementation of the largest investment project in recent decades has been underway since 2017. It involves the phased replacement of three absorption towers. One of the world leaders in the production of sulfuric acid equipment, the Canadian company CHEMETICS, was chosen as the project designer and equipment supplier. The total value of the contract exceeds USD 10 million. The first tower was replaced in 2017.

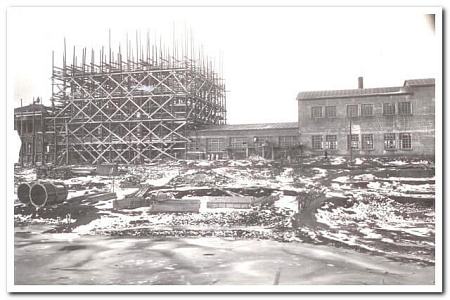

PMU Branch launched the production of micro-prilled urea

PMU Branch launched the production of micro-prilled urea

PMU Branch launched the production of micro-prilled urea with a grain size of 0.3-1.0 mm. For packaging this product a new building has been constructed on the Perm production site for the first time in decades. Project investment totalled 72 million roubles (VAT included). Samples of micro-prilled urea were sent to consumers and enjoyed very good feedback. As a result the company began export shipments of the new product. The maximum production and sales volume of micro-prilled urea at PMU Branch is estimated at 20 thousand tonnes a year. This is approximately 20% of the global consumption.

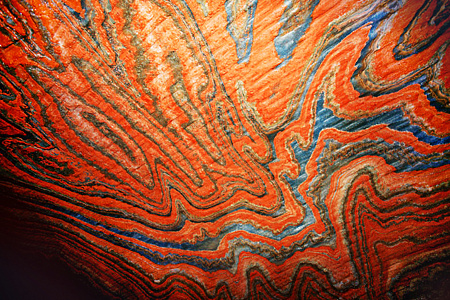

VMF improves the quality and increases the output of clarified phosphoric acid

VMF improves the quality and increases the output of clarified phosphoric acid

VMF Branch introduced a line of new filter presses designed to improve the quality and increase the output of clarified phosphoric acid. This technical solution was dictated by the company’s needs for a high-quality pure product, since it directly affects the quality of water-soluble fertilisers, for which the clarified acid is the main semi-finished product. Today, the output of 100% clarified P2O5 is 50 thousand tonnes per year. The inclusion of new plants created additional opportunities for the sale of this commercial product. The demand for P2O5 in the chemicals market has been steadily growing.

KCCW Branch started the ‘Online Advisor for DGD’ project

KCCW Branch started the ‘Online Advisor for DGD’ project

At the end of 2018, as part of the digitalisation programme called ‘Artificial Intelligence and Machine Learning’, KCCW Branch started the implementation of an online advisor for a pilot drum type granulator-dryer (DGD). At the initial phase of the project, SAP in partnership with BDO developed a digital model of the drying and granulation process and trained a dedicated advisor. Historical data tests proved the sufficient accuracy of the digital model. A joint team of the customer and the contractor confirmed the potential efficiency of the project.

The online advisor implementation is a pilot project related to efficiency improvement of URALCHEM’s production processes.

On 1 August 2017, URALCHEM, JSC completed the reorganisation process in the form of merging Mineral Fertilizers, JSC (Perm) with URALCHEM, JSC as PMF Branch, with the termination of the activities of Mineral Fertilizers, JSC as an independent legal entity. The purpose of the reorganisation was to improve the efficiency of the companies comprising URALCHEM Group.

Voskresensk Mineral Fertilizers, JSC (VMF) has produced the first batch of a new range of water-soluble compound fertilisers for the open ground, under the Aqua Drop brand. They include six grades of compound nitrogen-potash (NK) and nitrogen-phosphate-potash (NPK) fertilisers. Their composition is different in a few ways from Solar fertilisers; for their production, other raw materials are used, which have been proven to be effective in the open ground. The company can now manufacture a highly effective and affordable type of agrochemical.

In addition, VMF has started the production of water-soluble Solar MAP and Solar NPK fertilisers sold at retail under the URALCHEM trademark and packaged in sealed bags of 1 kg, in addition to the production of granulated potassium chloride and NPK fertilisers of various grades. The use of small bags is because of the high demand for fertilisers from gardeners and small farmers.

Agreements on incorporation of URALCHEM’s own dealerships in the Russian regions are signed with governments of various areas of the Central, Southern, Volga, Far East, and Siberian Federal Districts. As of the year end, seven points of the holding products sales were opened in the Russian regions.

VMF has switched to commercial production of water-soluble fertilizers. Implementation of the major investment project began in 2011. It resulted in development of the state-of-the-art process of water-soluble MAP production from wet-process phosphoric acid, a process with no global peers. MAP is both a fertilizer as it is, and a feedstock for production of complex water-soluble fertilizers.

Within the scope of the national program of import phase-out, Azot Branch commenced production of granulated amine. The project, valued in excess of 110 million rubles, has been implemented jointly with Uralkali specialists. This product can be widely used in the mining, pharmaceutical, chemical, and other industries. It fully corresponds to its foreign analogues, but it is cheaper and logistically more convenient.

USC was created in early 2013 to unify and optimize URALCHEM divisions' accounting processes in a single multifunctional center. In particular, to process financial information and prepare financial reports by Russian and international standards, manage tax records and treasury operations as well as establish and maintain unified information and telephone systems of the Company.

The Company’s product range was expanded now boasts 15 new products, with five more grades under development. In particular, sales of seven new NPK grades started for high-margin crops in Latin America. Also expanded was the Company’s range of liquid products to complement the NPK Solar fertiliser line.

Uralchem was the first company in Russia to introduce MultiStart, a line of biomodified fertilisers, which was improved to suit a wider range of crops.

Uralchem also ran a series of field tests to use aerial drones for fertilisation, the first among other fertiliser producers. With this technique, fertiliser can be applied remotely in almost any conditions.

On 1 March 2023, Voskresensk Mineral Fertilisers JSC completed a reorganisation process and was merged with Uralchem as its branch. The reorganisation aims to increase Uralchem Group’s operating efficiency by reducing the number of intragroup transactions, considerably cut administrative and management expenses, and improve financial flow management.

In 2023, Uralchem Group’s humanitarian assistance included the supply of 20,000 tonnes of complex fertilisers to Malawi, 34,000 tonnes of fertilisers to Kenya, 23,000 tonnes of fertilisers to Zimbabwe, and 34,000 tonnes of fertilisers to Nigeria.

Uralchem Group is committed to donating approximately 300,000 tonnes of mineral fertilisers to developing nations to alleviate the unprecedented global food crisis and prevent crop losses in countries that face the risk of famine. The charity shipments to Africa are facilitated by the United Nations World Food Programme.

For the first time in its history, Uralchem appeared on the list of Russian leaders of sustainable development, corporate responsibility and reporting issued by the Russian Union of Industrialists and Entrepreneurs (RSPP). For its performance in 2023, Uralchem achieved a Group A (which is the highest group) ranking in the Sustainable Development Vector index and a Group B+ ranking in the Responsibility and Transparency index.

The Responsibility and Transparency index analyses the quality of corporate social responsibility disclosures and identifies priority directions for further development of sustainability practices, while the Sustainable Development Vector index assesses the environmental and social performance history of the participating organisations.

Uralchem shipped over 23,000 tonnes of the NPK fertilisers to Lomé, the capital of the Togolese Republic, from where the fertilisers were transported to Burkina Faso. The shipment was made completely free of charge and is part of Uralchem’s humanitarian project to supply fertilisers to African countries. In addition, Uralchem and Uralkali jointly delivered a 20,000 tonne batch of NPK fertilisers to Malawi via Mozambique.

The humanitarian project is part of Uralchem’s efforts to address the global food crisis and responds to UN Sustainable Development Goal No 2 — “End hunger, achieve food security and improved nutrition and promote sustainable agriculture”.

The publication of its first ESG report marked another step in Uralchem’s sustainability transformation journey and supported the implementation of the Company’s ESG Strategy adopted in 2021. Uralchem confirms its commitment to follow principles of sustainable development, support employee and community well-being, and contribute to food security.

The ESG Report was prepared in line with reporting standards of the Global Reporting Initiative (GRI) and Sustainability Accounting Standards Board (SASB).

Uralchem Innovations launched a pilot plant making pea isolate – a high-purity natural vegetable protection produced from yellow peas. The isolate can be used in meat and milk alternatives, sport and dietetic nutrition, gluten-free and protein-rich breads, groceries and pastries.

Located at the Skolkovo Centre of Innovations, the pilot plant also includes an agricultural and a chemical laboratory.

Uralchem launched production of complex mineral fertilisers at GEO NPK LLC in Chernyakhovsk (Kaliningrad Region, Russia). GEO NPK will be making products containing nitrogen, phosphorus, potassium, and other mesoelements and microelements in one granule. With this new operation, Uralchem’s product portfolio will be expanded by more than 100 fertiliser brands.

In addition, production of AdBlue was started in Yartsevo, Smolensk Region. AdBlue is a liquid chemical, which is used to treat diesel engine exhaust gases and which reduces the content of nitrogen oxides in exhaust gases by 90%. The monthly capacity of the new plant is about 1,250 tonnes with a possible expansion to 2,500 tonnes.

Uralchem’s Board of Directors approved the Company’s ESG Strategy until 2025. The document ensures a systemic approach to the development of sustainability practices and lays the foundation for a further ESG transformation of the business. Uralchem views the ESG Strategy as an integral part of its overall corporate strategy and plans to integrate the principles of sustainable development into all main business processes. The Company’s key priorities cover global issues, sustainable production, product quality and safety, environmental performance within areas of its operations, and well-being of employees.

At the request of Uralchem, Togliattiazot (ToAZ) held an extraordinary general shareholders’ meeting (EGM) on 27 November 2021. At the EGM, ToAZ shareholders resolved to terminate prematurely powers of the management company (Togliattiazot Corporation JSC) and members of the board of directors, followed by an election of a new board of directors. The resolutions of the EGM were aimed at improving the financial and economic efficiency of ToAZ, and restoring law and order at the enterprise. Uralchem conducted the EGM strictly in accordance with the applicable legislation and the final judgement of the Arbitrazh Court of the Samara Region dated 22 November 202.

The Group's holding companies, Uralchem Holding PLC and CI-Chemical Invest Limited, re-domiciled from Cyprus to Russia. Thus, the entire asset management chain of Uralchem Group is now located within the Russian Federation. Tax contributions from the previously foreign assets of the Group will now be flowing to the Russian budget.

New product of the Azot Branch – feed salt – conquers the market

New product of the Azot Branch – feed salt – conquers the market

Sodium chloride technical grade (feed salt) has become an important product in the company's line of feed additives. The entire volume of feed salt is sold in the domestic market. It is in demand by livestock breeders. The product is a mineral additive and is used to enrich the ration of cattle, poultry, and other domestic animals with sodium and chlorine. The production of feed salt became possible through the implementation of an investment project. Within the framework of the project, a new nitrite and nitrate facility was built, where sodium chloride crystals are converted into sodium chloride technical grade — feed salt.

AM-76 ammonia unit at the KCKK Branch has been upgraded

AM-76 ammonia unit at the KCKK Branch has been upgraded

The URALCHEM Group allocated about 2 billion rubles for the repair and upgrade of the AM-76 ammonia unit. Such major works are carried out every twenty years. The reforming furnace pipes and lining were replaced. At the same time, an investment project was implemented to increase the unit's productivity; a syngas compressor was upgraded, which at that time was the bottleneck in the process chain. Almost all the plant's services and contractors took part in the work. As a result, the Company's specialists ensured reliable operation of the equipment and increased the capacity of the ammonia unit by 85 tons per day in winter.

URALCHEM was awarded the IFA gold medal

URALCHEM was awarded the IFA gold medal

The International Fertilizer Association (IFA) has awarded the PMU Branch of URALCHEM USC with the "Best in the Industry" gold medal for responsible production management. The PMU Branch was the first fertilizer producer in Russia to receive IFA certification under the Protect & Sustain program in August 2017. In February 2019, the plant successfully passed an intermediate check and confirmed the validity of this certificate.

A facility for urea packing in big bags was built at PMU

A facility for urea packing in big bags was built at PMU

The PMU Branch of URALCHEM USC received permission to put into operation a new facility for urea packing in soft containers (big bags). The corresponding certificate was signed by specialists of the Department of Urban Planning and Architecture of Perm on December 27, 2019.

The facility contains two high-speed filling machines and a transfer unit. The produced urea goes to the newly constructed building. In the packaging facility, the product is accumulated in bunkers, and then, using filling machines, is distributed into 800 kg big bags. A loading area with an overhead crane on stationary supports is equipped next to the packing facility. Here, urea bags are loaded into gondola cars. Also within the scope of the project, the construction of a gondola car preparation area continues. The total investment amounts to 530 million rubles. The result of the project implementation will be the opportunity, if necessary, to pack the entire volume of urea produced in the PMU Branch in big bags.

The investment project "Technical re-equipment of UKL-7 units and production of magnesium nitrate solution" of shop No. 5 was implemented. The project value is 254 million rubles.

After the upgrade, the capacity of the units has increased by more than 50 tons per day. Due to the elimination of an explosive substance – natural gas – operational safety has increased. The work carried out made it possible to increase the productivity of the units by at least 1 ton per hour, as well as to improve the environmental characteristics of production and improve the working conditions of employees.

During the upgrade of No. 5A department of the non-concentrated nitric acid production, work was also carried out to change the supply of circulating water to these units. The implemented actions resulted in the connection of additional circulating water facilities, which make it possible to increase the cooling efficiency of heat-exchange process equipment and to increase the reliability of circulating water supply due to the possibility of switching between water circulation cycles when eliminating defects and carrying out shutdown repairs in other workshops of the branch.

VMF has completed the second stage of a massive investment project for upgrade of sulfuric acid production

VMF has completed the second stage of a massive investment project for upgrade of sulfuric acid production

As part of the project, the A2 final absorption tower was replaced. During the shutdown period, the tower, which ensures the capture of pollutants before they are released into the atmosphere, was replaced. The cost of the second stage of the project amounted to 232 million rubles. In 2019, its successful completion allowed the enterprise to enter stable production of sulfuric acid at design loads. The implementation of the largest investment project in recent decades has been underway since 2017. It involves the phased replacement of three absorption towers. One of the world leaders in the production of sulfuric acid equipment, the Canadian company CHEMETICS, was chosen as the project designer and equipment supplier. The total value of the contract exceeds USD 10 million. The first tower was replaced in 2017.

PMU Branch launched the production of micro-prilled urea

PMU Branch launched the production of micro-prilled urea

PMU Branch launched the production of micro-prilled urea with a grain size of 0.3-1.0 mm. For packaging this product a new building has been constructed on the Perm production site for the first time in decades. Project investment totalled 72 million roubles (VAT included). Samples of micro-prilled urea were sent to consumers and enjoyed very good feedback. As a result the company began export shipments of the new product. The maximum production and sales volume of micro-prilled urea at PMU Branch is estimated at 20 thousand tonnes a year. This is approximately 20% of the global consumption.

VMF improves the quality and increases the output of clarified phosphoric acid

VMF improves the quality and increases the output of clarified phosphoric acid

VMF Branch introduced a line of new filter presses designed to improve the quality and increase the output of clarified phosphoric acid. This technical solution was dictated by the company’s needs for a high-quality pure product, since it directly affects the quality of water-soluble fertilisers, for which the clarified acid is the main semi-finished product. Today, the output of 100% clarified P2O5 is 50 thousand tonnes per year. The inclusion of new plants created additional opportunities for the sale of this commercial product. The demand for P2O5 in the chemicals market has been steadily growing.

KCCW Branch started the ‘Online Advisor for DGD’ project

KCCW Branch started the ‘Online Advisor for DGD’ project

At the end of 2018, as part of the digitalisation programme called ‘Artificial Intelligence and Machine Learning’, KCCW Branch started the implementation of an online advisor for a pilot drum type granulator-dryer (DGD). At the initial phase of the project, SAP in partnership with BDO developed a digital model of the drying and granulation process and trained a dedicated advisor. Historical data tests proved the sufficient accuracy of the digital model. A joint team of the customer and the contractor confirmed the potential efficiency of the project.

The online advisor implementation is a pilot project related to efficiency improvement of URALCHEM’s production processes.

On 1 August 2017, URALCHEM, JSC completed the reorganisation process in the form of merging Mineral Fertilizers, JSC (Perm) with URALCHEM, JSC as PMF Branch, with the termination of the activities of Mineral Fertilizers, JSC as an independent legal entity. The purpose of the reorganisation was to improve the efficiency of the companies comprising URALCHEM Group.

Voskresensk Mineral Fertilizers, JSC (VMF) has produced the first batch of a new range of water-soluble compound fertilisers for the open ground, under the Aqua Drop brand. They include six grades of compound nitrogen-potash (NK) and nitrogen-phosphate-potash (NPK) fertilisers. Their composition is different in a few ways from Solar fertilisers; for their production, other raw materials are used, which have been proven to be effective in the open ground. The company can now manufacture a highly effective and affordable type of agrochemical.

In addition, VMF has started the production of water-soluble Solar MAP and Solar NPK fertilisers sold at retail under the URALCHEM trademark and packaged in sealed bags of 1 kg, in addition to the production of granulated potassium chloride and NPK fertilisers of various grades. The use of small bags is because of the high demand for fertilisers from gardeners and small farmers.

Agreements on incorporation of URALCHEM’s own dealerships in the Russian regions are signed with governments of various areas of the Central, Southern, Volga, Far East, and Siberian Federal Districts. As of the year end, seven points of the holding products sales were opened in the Russian regions.

VMF has switched to commercial production of water-soluble fertilizers. Implementation of the major investment project began in 2011. It resulted in development of the state-of-the-art process of water-soluble MAP production from wet-process phosphoric acid, a process with no global peers. MAP is both a fertilizer as it is, and a feedstock for production of complex water-soluble fertilizers.

Within the scope of the national program of import phase-out, Azot Branch commenced production of granulated amine. The project, valued in excess of 110 million rubles, has been implemented jointly with Uralkali specialists. This product can be widely used in the mining, pharmaceutical, chemical, and other industries. It fully corresponds to its foreign analogues, but it is cheaper and logistically more convenient.

USC was created in early 2013 to unify and optimize URALCHEM divisions' accounting processes in a single multifunctional center. In particular, to process financial information and prepare financial reports by Russian and international standards, manage tax records and treasury operations as well as establish and maintain unified information and telephone systems of the Company.