Environmental protection

Improving environmental safety and protecting the nature are always given priority as we fulfil and develop our production potential. Every year, our plants develop environmental plans and set short-term goals that help us reduce air emissions, reduce quantity and improve quality of wastewater, reduce hazardous waste, and increase waste recycling.Uralchem constantly monitors its plants’ environmental impact and compliance through special monitoring, environmental design of all reconstruction and modernisation projects etc.

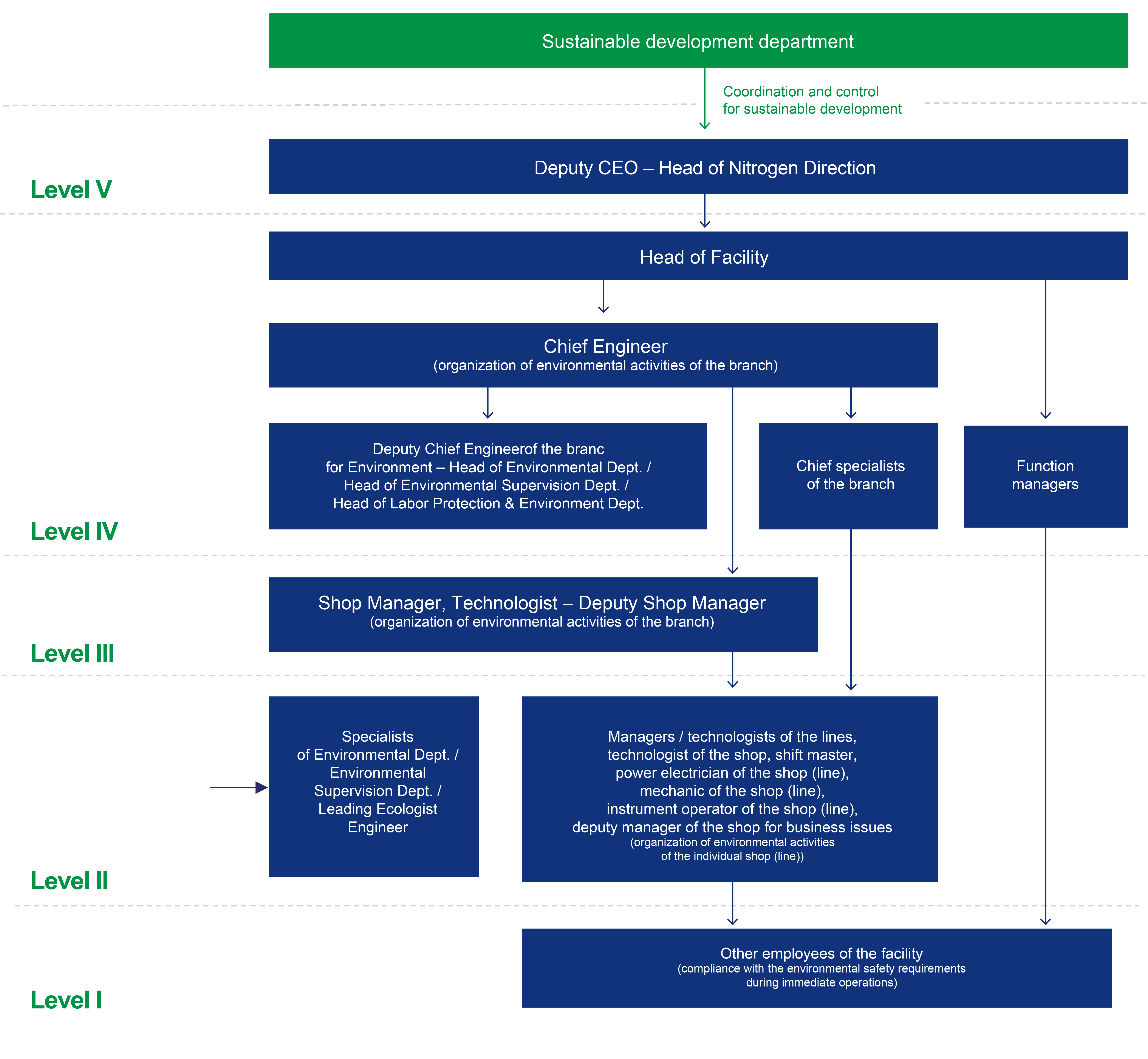

Environmental protection and safety management framework

Environmental issues are discussed at meetings of the Board of Directors including as part of the approval of environmental projects, and also at meetings of the Strategy and Investment Committee. The annual reports approved by the Board of Directors provide specific information on these matters. In August 2025, Uralchem published its 2024 ESG Report, which contains more detailed information on the Company's environmental activities.

Policies and other key documents

All production facilities of the Company have implemented and are actively using integrated management systems (IMS). As part of the IMS, certain policies (including an environmental policy) have been developed and approved. These documents are based on the following key principles:

Environmental management system

The environmental management system (EMS within the IMS) of each production facility of the Company is certified for compliance with the ISO 14001:2015 requirements. Every three years, the facilities’ EMS undergo independent certification according to this standard, which is carried out by independent international certification bodies is annually confirmed by a supervisory audit.

The EMS of the KCKK and Azot branches are also certified under the Russian standard GOST R ISO 14001-2016, which is an equivalent of the corresponding international standard.

In 2017, Uralchem became the first company in Russia to be certified under the Protect & Sustain programme of the International Fertilizer Association (IFA). The Protect & Sustain programme’s criteria include the requirements of three international standards ISO 9001:2015, 14001:2015, 45001:2018, and the RC 14001 (Responsible Care) specification. Based on the certification results, the Company was issued a Product Steward Excellence certificate. This is the highest level of recognition for non-European fertiliser producers. In 2020, specialists from the SGS certification body renewed the certificate with confirmation of the Excellence recognition level.

EMS supervisory audit

| Group company | EMS supervisory audit | EMS re-certification audit | ||||||

|---|---|---|---|---|---|---|---|---|

| ISO 14001:2015 | GOST R ISO 14001-2016 | ISO 14001:2015 | GOST R ISO 14001-2016 | |||||

| KCCW Branch | ||||||||

| KCCW Branch |

|

|

|

|

||||

| Azot Branch | ||||||||

| Azot Branch |

|

|

|

|

||||

| PMU Branch | ||||||||

| PMU Branch |

|

|

||||||

| VMU Branch | ||||||||

| VMU Branch |

|

|

||||||

Successfully completed in 2022

Successfully completed in 2022

Successfully completed in 2023

Successfully completed in 2023

EMS certification of plants by independent organisations allows Uralchem not only to ensure transparency of production and management processes, high quality of products, environmental protection and safety, but also to significantly increase the efficiency of business processes and quality of management, and to strengthen trust on the part of customers and regulatory authorities.